Steel Posts;

Concrete Posts;

Wooden Posts ( Timber posts shall be in lengths and comply with the requirements of AASHTO M168 or BS 457.)

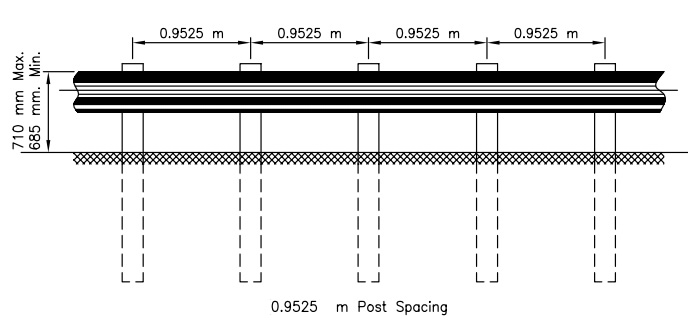

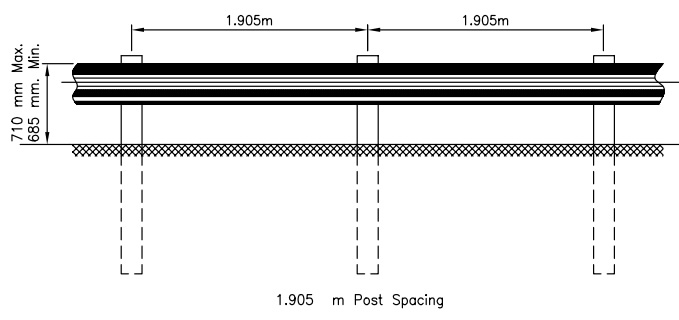

Guardrails can be installed with posts of different spacings to meet design requirements:

The holes for the posts shall be of sufficient size to permit proper setting of the posts and to allow sufficient room for backfilling and tamping. At least 1 m of the posts shall be embedded in the ground.

The holes for the posts shall be spaced to suit the standard length of guardrail supplied. Where shown on the drawings or directed by the Engineer, posts shall be set at half spacing. The hole for the concrete block at the end of a length of guardrail shall be neatly excavated and the top 120 mm shall be shuttered.

The posts, spacer blocks (if applicable) and guardrails shall be completely erected, set true to line and level, so that the rail is at the required height above the level of the completed road shoulder and the lap shall be in the direction of the traffic movement. The guardrail shall be suitably braced to prevent any movement, and all bolts tightened prior to any backfilling of holes.

After the Engineer has signified his approval of the guardrails so erected, the holes shall be backfilled with a 12:1 soil:cement mixture. The material may be either mixed by hand or mechanically and the correct quantity of water added to ensure that the mixture is placed at or near to optimum moisture content. The mixture shall then be placed and thoroughly rammed in layers not exceeding 100 mm compacted thickness. The approach ends, where the guardrail has to be bent down and anchored, shall be constructed as shown on the drawings.

When the backfilling is complete and the bracing removed, the posts must be rigid, vertical and the guardrail true to line and level and firmly fastened to the posts. Excess excavated material shall be disposed of as directed by the Engineer.

All guardrails shall be erected in such a way that there are no projecting ends that might interfere with or endanger traffic. The edges and the center of the rail element shall contact the spacer block, or the post where no spacer blocks are used. Guardrail elements shall lap in the direction of the traffic and, if specified, guardrails shall be provided with terminal sections, which shall be lapped on the traffic face. All splices of rail elements shall be at a post, and plate ends shall make contact through the entire area of the splice.

Guardrails installed with non-buried, blunt ends shall employ reflective tape on the blunt end. Such preformed reflective tape shall be furnished in 100mm wide rolls conforming to ASTM D 4592, type 1.

The completely installed guardrails in neat conditions and the system with no visible deviations from line and grade. The posts are straight and vertical. The rail beam is warped, but in a vertical plane parallel to the road centerline except at flared sections. The galvanized surface on the rail shall be smooth and continuous, free from abrasions and scratches.

All foundation concrete in contact with ground or ground water shall be Portland-pozzolan cement concrete conforming to specification 03310 for blended cement Pozzolan shall be 15% to 20% replacement of Portland cement.

Concrete foundations for intermediate posts to be 600 dia. by 1200 deep.

Locking tabs shall be set perpendicular to the flow of traffic.

Where a portion of the foundation is above grade the top edges shall have a 20 chamfer.

Add: No. 09 Neo-Tech District, Development Zone, Dezhou, Shandong Email: info@highwayguardrail.org URL: https://www.highwayguardrail.org